While anyone can get there by hand-copying the program and entering it into the new Matrix control, this is a tedious and error-prone method. MazaCAM is breakthrough technology that transforms the legacy Mazatrol programs to the new Matrix controls, enabling the shop to be up and running in a minimum time.

The e-Machine and the Integrex:

Many customers who buy the e-Machine (which is milling-based) also have an earlier Integrex (which is turning-based). MazaCAM converts between these entirely differently-based control families. There are literally hundreds of tricky nuances that are handed in this extensive advanced conversion. MazaCAM handles Mazatrol programs from all earlier generations of Integrex: T3, T32, T-Plus, Fusion640MT, and Fusion-MT-Pro.

For 33 years SolutionWare Corporation has been continuously advancing software and training that gives CNC shops the flexibility to utilize all their CNC equipment for the greater productivity of their shop. For more information, call 408-249-1529 or toll-free 1-888-322-3226.

Back to Top

PRESS RELEASE

Silicon Valley, CA - July, 2003

Contact:

Martin J. Aguilar

VP Marketing

SolutionWare Corporation

(408)249-1529

Get More Done in Less Time

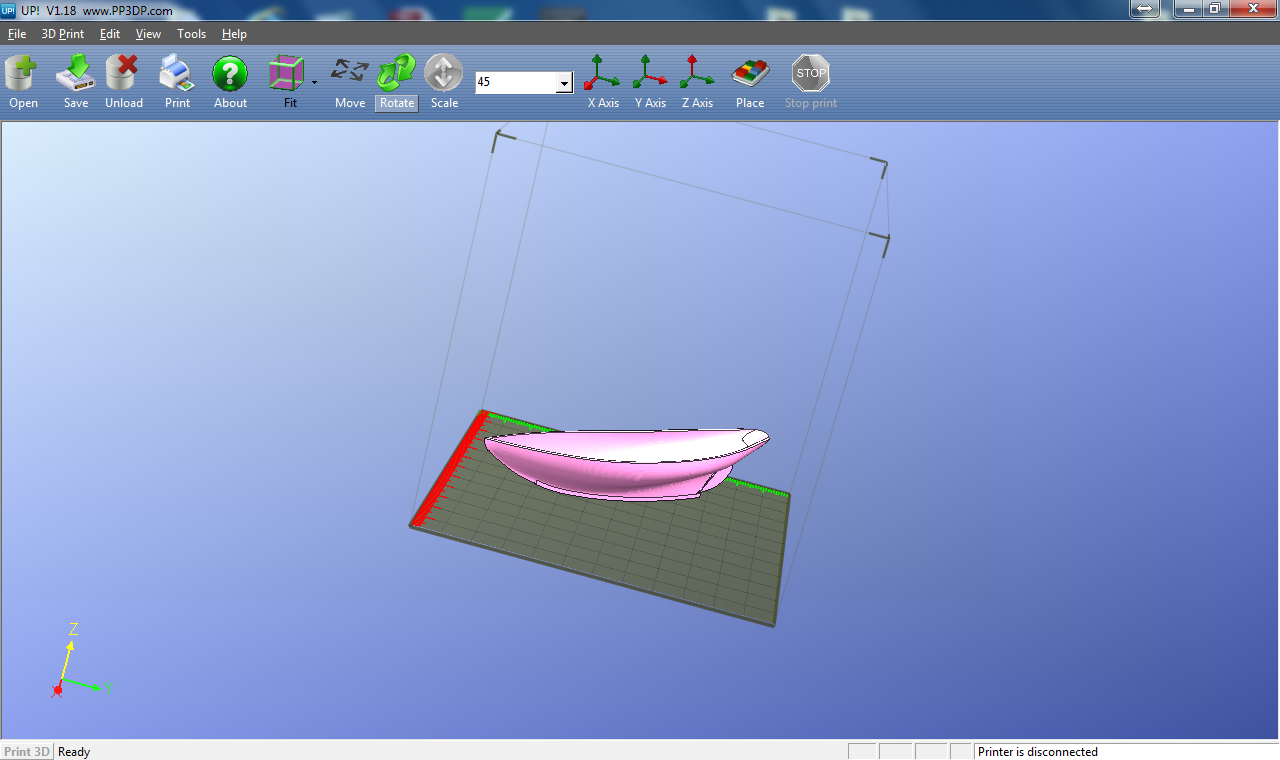

SolutionWare Corp. has just released GeoPath V4.1. The software includes a set of more powerful, easier to use features to increase production and cut more parts in less programming time.

Get more programming done in less time

The 'NC Utilities bar' is said to give users direct control and command of their NC programs. Creating tool-sheets, calculating run-time, communicating to the machine are just some of the functions accessible with a click of the mouse. During programming, the 'IGES repair function' reduces programming time by automatically checking the incoming CAD file for errors and fixing them. GeoPath V4.1 also encompasses the ability to extract the part geometry from surface files in a matter of seconds, allowing for easier and faster programming of 2.5 Axis mill cuts. Numerous 3D enhancements were added to the software to facilitate and lessen programming time for complex surfaces. These include the ability to convert surfaces to different kinds and other tools that give the user a variety of methods of cutting that a programmer might deem better for different. situations.

Cut more parts in less time

The 'Plunge Roughing' cut kind gives programmers the ability to maintain tighter tolerances and remove material faster while applying more force from the machine in the Z direction. It is available in numerous path-kinds such as: back and forth, spiral from the outside in, spiral from the inside out, contour or user custom path. Users are more in control of their production and programming time.With the new enhanced 'Helical Threading', threading blind or through holes is done faster and with more control. It also includes abilities to do taper threads, inside or outside threads, feedrate compensation, lead-in/out control, Tool-Radius-Compensation, features for cutting hard materials, and use single or multiple thread tools. The Lathe 'Step-Peck Roughing' also speeds up production by eliminating the time spent removing chips wrapped on the tools during roughing operation. It is also a useful tool for roughing out deep or complex groove shapes with smaller groove tools.

More graphical feedback, Less time verifying

GeoPath V4.1 also incorporates a number of features to ease programming. The 3D Surface and 2-Axis Lathe rendering help programmers visualize the final part while programming. The 'Tool-Library Selection Image' instantly shows the user a picture of each tool including the tool holder when scanning through the library list, which makes the selection process more certain and faster. The “Tool Orientation' picture makes it easier for programmers to identify the tool orientation and angles used during the machining process.

GeoPath V4.1 is available in modules to suit your shop's needs. Modules also include auto-programming, EDM and MazaCAM (Mazatrol output module). Call 408.249.1529, or email [email protected] for more information.

Back to Top

PRESS RELEASE

Silicon Valley, CA - July, 2002

Contact:

Martin J. Aguilar

VP Marketing

SolutionWare Corporation

(408)249-1529

MazaCAM Tool-Data Editor

The Off-line Tool-Data Editor integrated in MazaCAM makes Mazatrol programming even easier for Mazatrol programmers.

SolutionWare announces its new enhancement to the MazaCAM Off-line programming system: Mazatrol Tool-Data editing. An addition added to make Mazatrol programming even faster.

In one convenient user-friendly screen, the user can create or edit his Mazatrol program, then simply switch to his Tool-Data and select or modify the necessary tools that he needs to run that job. This is also done in combination with using the Tool-File from the Mazak. The user will be able to modify the Nominal Diameter, the angles of the tools, the tool material etc. just like doing it on the Mazak control itself. The Tool-Data file would be downloaded ONCE from the machine and stored on the computer for future modifications and programming.

With this new enhancement, the programmer can have everything ready (program, tools, time estimate, etc.) for the job and simply send it to the machine for programming. All the work is done in the office on the computer while the machine is running other jobs.

As a CNC programmer, reducing downtime is very important. That is exactly what Richard Esser from Ermco Manufacturing experienced: 'Since installing MazaCAM, I have found that down-time on our Mazaks has been reduced by 80%. Now we get the most of our Mazaks.' Scott Reid from Circle Gear Manufacturing increased his programming time: ' With the MazaCAM software, intricate shapes that would take hours to program manually, literally took minutes with your system.'

More information about MazaCAM can be obtained by calling SolutionWare at 408-249-1529, or toll-free in the USA 1-888-3CAD-CAM